Material Handling

Material handling equipment is used to transport, lift or convey significant loads efficiently and to reduce the risks of damage or injury. For example, the mast guide bearings and leaf chain on fork lift trucks are the key elements to keeping a fleet running 24/7.

The material handling industry covers a wide range of materials, applications, and processes. Material handling incorporates various automated, semi-automated, and manual equipment to move, protect, store, and control the products used in different facilities, including manufacturing plants, warehouses, and distribution centers. This equipment can range from forklift trucks to conveyor systems to automated guided vehicles.

Efficient material handling results in better customer service, reduced inventory, streamlined deliveries, and lower costs. To ensure optimal performance and functionality, material handling equipment and machinery must incorporate high-quality bearings.

Emerson Bearing is a trusted distributor of top-quality conveyor bearings, mast guide bearings, cam follower bearings, double row bearings, and leaf chain bearings for material handling equipment at competitive prices. Learn more about how bearings are used in these systems, common types and applications of bearings for material handling, and specialty bearing options.

The Role of Bearings in Material Handling Equipment

Material handling equipment, such as conveyors, forklifts, hoists, and pulleys, uses bearings in many mechanisms and assemblies to create smooth and steady motion, even when supporting heavy loads. Bearings are integral in these systems for:

- Reducing friction. Bearings are very smooth and hard so they roll, rotate, and glide easily, which cuts down on friction and energy loss. This helps parts and equipment last longer and reduces maintenance needs.

- Improving load distribution. Bearings distribute loads across their contact surfaces, which reduces stress on components and makes movement more smooth.

- Ensuring durability and reliability. High-quality bearings from Emerson Bearing keep equipment operating efficiently and extend its useful life. As a result, production levels are maintained or even increased, as downtime due to bearing maintenance or worn parts decreases.

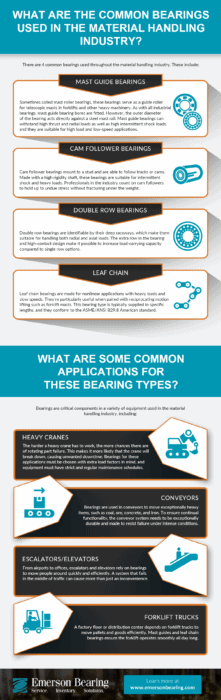

What Are Common Bearings Used in the Material Handling Industry?

Material handling equipment, such as conveyor systems, forklifts, cranes, and hoists, rely on a wide variety of bearings to ensure this equipment operates smoothly. There are four common bearings used for these applications. These include:

Mast Guide Bearings

Sometimes called mast roller bearings, these bearings serve as a guide roller for telescopic masts in forklifts and other heavy machinery. As with all industrial bearings, mast guide bearing bores are fitted. However, the outer diameter of the bearing acts directly against a steel mast rail. Mast guide bearings can withstand high thrust and radial loads as well as high intermittent shock loads, and they are suitable for high load and low-speed applications.

Cam Follower Bearings

Cam follower bearings mount to a stud and are able to follow tracks or cams. Made with a high rigidity shaft, these bearings are suitable for intermittent shock and heavy loads. Professionals in the industry count on cam followers to hold up to undue stress without fracturing under the weight.

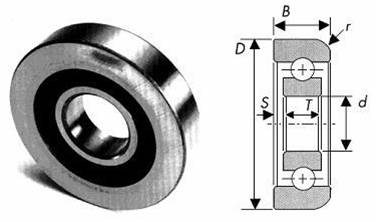

Double Row Bearings

Double row bearings are identifiable by their deep raceways, which make them suitable for handling both radial and axial loads. The extra row in the bearing and high-contact design make it possible to increase load-carrying capacity compared to single row options.

Leaf Chain

Leaf chain bearings are made for nonlinear applications with heavy loads and slow speeds. They’re particularly useful when paired with reciprocating motion lifting such as forklift masts. This bearing type is typically supplied in specific lengths, and they conform to the ASME/ANSI B29.8 American standard.

What Are Some Common Applications for These Bearing Types?

Bearings are critical components in a variety of equipment used in the material handling industry, including:

Heavy Cranes. The harder a heavy crane has to work, the more chances there are of rotating part failure. This makes it more likely that the crane will break down, causing unwanted downtime. Bearings for these applications must be chosen with extra load factors in mind, and equipment must have strict and regular maintenance schedules.

Conveyors. Bearings are used in conveyors to move exceptionally heavy items, such as coal, ore, concrete, and iron. To ensure continual functionality, the conveyor system needs to be exceptionally durable and made to resist failure under intense conditions.

Escalators/Elevators. From airports to offices, escalators and elevators rely on bearings to move people around quickly and efficiently. A system that fails in the middle of traffic can cause more than just an inconvenience.

Forklift Trucks. A factory floor or distribution center depends on forklift trucks to move pallets and goods efficiently. Mast guides and leaf chain bearings ensure the forklift operates smoothly all day long.

Specialty Bearing Solutions for High-Demand Environments

In addition to standard bearings, Emerson Bearing can source almost any time of hard-to-find or specialty bearing for conveyor, forklift, crane, and niche material handling applications. With over five decades of experience, our team At Emerson Bearing, our team is familiar with many brands, types, and configurations of bearings, bushings, seals, and shaft devices and can advise you on available options.

We are committed to providing responsive and helpful customer service, including helping you procure the best bearing for your application based on your requirements and restrictions.

Material Handling and Conveyor Bearings From Emerson Bearing

Material handling is a complex industry, one that requires an in-depth understanding of the inner workings of your machinery. At Emerson Bearing, our experts are dedicated to finding which bearing will work best for your needs. We understand that no two customers and no two use cases are alike, so we are here to determine the ideal solution regardless of how complex your application is.

We maintain a wide range of bearings in stock in sizes ranging from 3 mm inner diameter to 5 ft. steel mill bearings. Our products are sourced from European, Asian, and North American manufacturers and are available at various competitive price points. Many bearing products are in stock and available for fast delivery the same- or next-day.

To learn more about our bearing products, or for help finding the best solution for your material handling application, please contact us today.

To learn more about our bearing products, including our high-quality bearings for conveyors and other material handling equipment, please contact us or request a quote for your project.