Pulp, Paper Converting and Printing

This vertical group of industries touches everyone every day. At every point in the process of going from pulp to print these bearings have to meet the highest standards. In the initial phase of creating paper the rolling bearings in a paper machine must meet extreme requirements: Moisture, very high temperatures, shaft deflections, high speeds and long running times.

The term “paper conversion” refers to the processes used to turn raw paper material into other products. These finished products—e.g., books, newspapers, packaging, labeling, etc.—are used in nearly every sector and industry. As a result, in the United States alone, the paper converting and printing industry is estimated to be approximately $400 million and rising.

The technologies used in paper converting and printing operations often rely on bearings to achieve precise, accurate, and smooth performance. If you need bearings for your paper converting and printing applications, the experts at Emerson Bearing have got you covered.

Overview of Paper Converting and Printing

Despite the growth of the digital world, the paper converting and printing industry remains a major player in the global economy. From newspapers to books to mailed and shipped items, paper products are an integral—yet often overlooked—part of our day to day lives.

The complete paper conversion process begins with raw material and ends with a finished product. It can include the following steps:

- Gathering raw fibers and melting it into pulp

- Bleaching, straining, flattening, and drying the pulp into a continuous roll of paper

- Cutting the master roll of paper into more manageable sizes

- Cutting and shaping the smaller rolls in the desired shape and size

There are many methods of completing the latter two steps of the paper conversion process. The two most common are:

- Slitting/Rewinding. This method involves unwinding and feeding the master roll through a series of blades to cut and slit the paper into smaller widths and then rewinding the cut/slit paper into new rolls.

- Precision Roll Sawing. This method involves cutting and slitting the master roll into smaller widths without unwinding and rewinding it.

What Are the Key Benefits of Paper Conversion?

The paper converting and printing industry affects our day to day lives in many ways, including with regard to the following:

- Products/Packaging. Many products we use on a daily basis are made from paper. In the consumer sector, we regularly utilize books, newspapers, magazines, and bags, while most—if not all—industrial and commercial companies use some form of paper packaging (e.g., boxes, cartons, packing paper, etc.) for their products.

- The industry has made significant advancements toward improving its environmental footprint. In addition to reducing its consumption of fossil fuels during the production of paper products, it has developed methods of recycling old and used paper products into new materials and products. The latter is important for reducing the overall size of landfills.

Bearing Solutions for Paper Converting and Printing

Many paper converting and printing systems use bearings to facilitate the rolling, cutting, and unrolling of paper materials. However, the type of bearing employed in the system varies depending on the production requirements. For example, slitters and rewinders require high-speed bearings and high-accuracy linear motion bearings.

At Emerson Bearings, we provide the following bearing solutions for paper converting and printing applications:

- Ball and roller bearings

- Cylindrical roller bearings

- Spherical roller bearings

- Free Running bearings

- One-way clutch bearings

- Cam followers

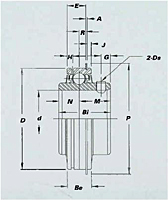

- Mounted units

- Oil seals

All of our bearing systems are built to the highest standards. They can withstand the demanding conditions of the industry, including high moisture, temperatures, speeds, and run times.

Partner With Emerson Bearing for Your Paper Converting/Printing Bearing Needs

Bearings are an essential component of paper conversion equipment. If you need bearings for your paper converting and printing facility, turn to the experts at Emerson Bearing. Our highly experienced team can help you find the right bearing solution for your application. For more information about our bearing solutions for paper converting and printing systems, contact us today. To discuss your bearing requirements with one of our experts, request a quote.

Special Solutions: Use of spherical roller bearings that conform to E1 design with superior load carrying capacity, low operating temperatures and high service life. Also should conform to running accuracy specifications T52BW.

The process of converting paper into a usable form has very different bearing requirements. Slitters and rewinders require high speed ball bearings and linear motion bearings that have high running accuracy.

Special Solutions: Use of ‘free running’ insert bearings and pillow blocks. These have modified seals and slingers on both sides which allow for low start up torque and effective sealing even in high heat applications. Printing on paper is the final phase. To achieve the required pin sharp print quality you must have high precision and wear free bearing supports for the print rollers. This insures that the impression cylinder is supported with as little clearance, and as much rigidity as possible and with very few runout errors. The NAO style needle bearing with offset cage packets has become the standard. Needle rollers, Cam Followers and yoke rollers are used extensively in the distributor roller drives, gripper shaft controls and throughout the presses

Contact our Marketing Specialists:

Pulp and Paper: Lee Holt – E-mail

Phone: 1.866.995.8763

Paper Converting and Printing: Rick Piracini – E-mail

Phone: 1.866.995.8765