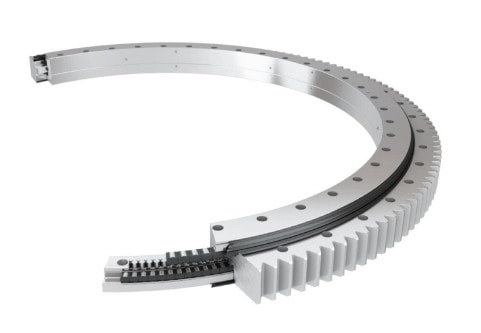

Types of Bearings

We offer a range of bearing types to support machinery in various industrial applications.

Industrial Applications of Bearings

Bearings have applications in all types of industries, though each individual bearing has its ideal uses. Common industrial applications of bearings include:

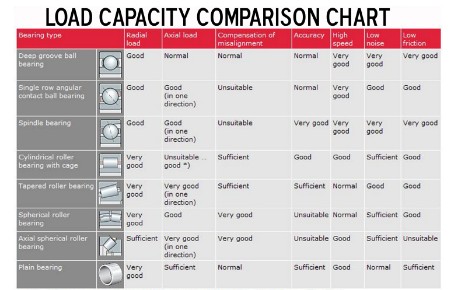

Factors Influencing Type of Bearing Selection

When choosing bearings for your application, consider the following:

Maintenance and Lubrication of Bearings

Bearing maintenance and lubrication are both important factors in prolonging the life of your bearings. Regular lubrication with oil or grease minimizes bearing friction and heat generation, while routine inspections help identify general wear and bearing damage early. Ideally, you should have an advanced monitoring system in place to assist in this, enhancing bearing failure detection to ensure timely troubleshooting and maintenance.

New Types of Bearings

The bearing industry continues to innovate to meet the needs of emerging equipment technology in various markets. Emerging bearings and bearing advancements include:

Smart bearings and condition monitoring

With integrated sensors to enable performance tracking in real time, these bearings support early detection of any issues for proactive maintenance.

Advanced materials and coatings

New bearings are coming on the market with material and coating advancements that improve their resistance to wear and corrosion for better durability in demanding environments.

Sustainable bearing solutions

Manufacturers are emphasizing environmental friendliness in addition to efficiency in their bearing designs

Ceramic hybrid bearings

These bearings combine ceramic balls with traditional steel races for superior bearing performance.