Metal Processing

The metal recycling and wire forming industries are crucial for manufacturing products. Metal recycling creates a way to manufacture new products without the need for new materials, while wire forming grants endless manufacturing possibilities to meet various needs. These industries rely on specialized equipment to perform numerous tasks, so it is important that they have the proper bearing solutions to ensure optimal performance.

Overview of Metal Recycling

Metal recycling allows manufacturers to convert used and scrap metals into raw metal for use in new products. Since metals can be recycled indefinitely without losing their desirable characteristics, metal recycling is very sustainable. Metal recycling is similar to other recycling processes as the materials must be collected and sorted into specific categories. The sorted materials are processed and shredded before they are melted, purified, and allowed to solidify, after which they are transported to manufacturers for further fabrication.

What are the Key Benefits of Metal Recycling?

Metal recycling offers a host of benefits, including:

- Preserving Natural Resources. Rather than depending on invasive and polluting mining processes, metal recycling allows manufacturers to source a variety of metal materials without contributing to environmental damage caused by mining operations.

- Reduced Emissions.Producing new metal uses a significant amount of energy and releases greenhouse gases into the atmosphere. Metal recycling requires less processing, thereby reducing air pollution.

- Energy Conservation. Since recycled metal has already been refined, it only has to be modified to meet the requirements of the new product; therefore, less energy is required to produce products from scrap metal when compared to harvesting new resources for the same thing.

- Economic Benefits. The metal recycling industry creates jobs, and exported recycled metals generate hundreds of billions of dollars in annual revenue.

- Reduces Waste. Recycling metals significantly reduces the amount of waste that ends up in landfills, which opens up space in already overcrowded landfill facilities.

Overview of Wire Forming

Wire forming is a metal fabrication technique that uses heating, cutting, bending, and other machining processes to create a metal shape. Common materials used in wire forming include stainless steel, steel, aluminum, and copper. An extremely cost-efficient process, wire forming is used to create components for automotive, aerospace, construction, military, and electrical equipment.

Wire forming offers a number of benefits, including:

- Custom Design Capabilities. Wire forming offers a high degree of versatility and customization.

- Reduced Setup.Unlike other manufacturing methods such as die casting, extrusion, and molding, wire forming requires very little initial setup for a quicker, more streamlined process.

- Quick Turnaround. Wire forming is a quick manufacturing process that allows for reduced turnaround time between product development and its release onto the market.

- Cost-Effective. Wire forming is inexpensive when compared to other metal fabrication techniques.

What are Bearing Solutions for Metal Recycling and Wire Forming?

Both metal recycling and wire forming require specialized equipment to perform a multitude of tasks. Bearings provide necessary movement and direction in many load-bearing and process applications, and they can be tailored to meet the needs of particular operations.

Wire forming applications require precision bearings that assist with the direction and manipulation of wire profiles throughout the manufacturing process. The most common bearings used in wire forming include:

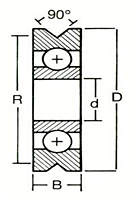

- Grooved Bearings.Groove bearings are characterized by a groove that can be produced in a range of custom angles and contours. They can be incorporated into ball bearings, cam followers, and yoke rollers to enhance wire forming operations.

- Straighteners are specifically designed to eliminate bends and irregularities as well as remove cast memory in the metal.

- Cam Followers.Cam followers are roller bearings designed to follow a cam profile to create linear motion from rotary motion.

Metal recycling requires durable, low-maintenance bearings that can withstand heavy loads and high shock. Common bearings incorporated into metal recycling processes include:

- Cylindrical Bearings.These bearings are characterized by cylinder-shaped rollers that are longer than their diameter. They are capable of withstanding heavier loads than ball bearings.

- Spherical Roller Bearings. Spherical roller bearings are specifically designed to carry heavy loads, even in the event of shaft misalignment or deflection. They also have the added feature of being easily assembled around a shaft.

Superior Quality Bearings for the Metal Recycling and Wire Forming Industry

At Emerson Bearing, we pride ourselves on providing our customers in the metal recycling and wire forming industries with quality bearings that meet and exceed industry standards for a wide range of applications. Our superior bearing designs are specifically engineered to meet the needs of a variety of load-bearing and motion-enhancing applications. To learn how our bearings can improve your processes, contact our experts today or request a quote.

Contact our Marketing Specialist:

Richard Furtado – E-mail

Phone: 1.866.995.8761