Marine Spares

The marine industry is vital for the global trade, commercial fishing, and recreation sectors. In fact, about 80% of all international trade by volume happens through the maritime industry. Because maritime transport is so vital, it requires 24/7 uptime, which means reliable spare parts.

The marine industry is currently facing increased environmental regulations regarding ship lubrications and emissions. This has posed challenges for manufacturing and sourcing compliant replacements, such as eco-friendly marine bearing grease. Marine bearings are some of the most important parts of marine vessels, helping marine engines transmit power and load. These bearings need to have enough tensile strength and load bearing capacity to withstand the harsh conditions of marine applications.

What Are the Common Bearings Used in the Marine Spare Industry?

There are 5 main types of bearings for marine propulsion engines.

Craft Split Bearing

Craft split bearings offer the benefits of conventional bearings with the added feature of easy assembly around a shaft. The complete assembly comes in halves to ease the installation, inspection, and replacement of pillow block bearings, which can be done without removing or disrupting other elements of the system.

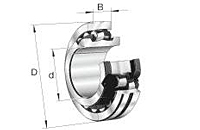

Split Spherical Bearing

This eliminates the need to remove gears or couplings, have drives dismounted and shaftings disassembled. They are drop in replacements for standard Spherical Roller bearings.

Some other additional bearings are:

Lead Bronze Bearing

The lead bronze bearing has two main layers underneath the flash layer, which protects the bearing from corrosion and dust when not in use. Once the bearing is in use, this layer flashes off, revealing a nickel layer that prevents tin and other elements from corroding the bearing’s metal. The next layer is made of lead bronze and has exceptional anti-seizing properties. A steel back provides structural support for the entire bearing.

Bi-metal Bearing

Bi-metal bearings are composed of two main layers. The first layer is aluminum tin—the principle component—which is followed by an aluminum bonding layer. This layer bonds to the steel back, which provides support and shape.

Tri-metal Bearing

The tri-metal bearing is mostly found in two-stroke propulsion engines, and it has three main layers. Underneath the flash layer—which protects the bearing in storage and flashes off during operation—is the overlay, which is made of a white metal like tin antimony copper. Next is the interlay layer, which acts as an corrosion-resistant barrier for the overlay. Finally, the lining provides a layer between the interlay and steel back support.

What Are Some Common Applications for These Bearing Types?

Lead bronze, bi-metal, and tri-metal marine bearings are most commonly found in the following applications:

- Marine gearbox bearings

- Stabilizer bearings

- Coupling covers for propeller shafts

- Stern shaft bearings

- Auxiliary machinery bearings

- Electric propulsion motor bearings

- Submarine steering gear bushings

- Submarine dive plane bushings

- Hydraulic resonance changing machines

- Sonar equipment

- Propulsion thrust blocks

- Rope guards

- Electronic and hydraulic thrust metering equipment

- Watertight door bushings

- Periscope guide bushings

Why You Should Choose Emerson for Your Marine Spare Bearing Needs

At Emerson Bearing, we provide high-quality bearings for niche markets around the world. Together with Action Bearing, our sister company, we have been delivering custom solutions to MRO and OEM clients for over 50 years. Our experts can help you develop the best solution for your marine spare application.

One of the most effective solutions for this industry is our split roller bearings, which enable quick bearing replacement in hard-to-reach locations like driveshafts. Our SL Sheave Wheel bearings provide extra high static and dynamic load ratings. Their rubber seals keep out dust and water. We also provide forklift leaf chains that are cut to length and maintain the speed of your unloading operation.

Our global freight capability allows us to serve every international market, so our bearings can meet your ship at the port. For more information about our services and products, contact us today.

Special Solutions: The first of many is the use of Split Roller bearings which allow for rapid bearing replacement especially at difficult to access locations, such as driveshafts. For the Sheave wheels, cranes and tensioner blocks we recommend the SL Sheave Wheel bearings. These provide extra high dynamic and static load ratings and come with rubber seals to prevent water and dust intrusion. To keep the unloading process from slowing down we can provide cut to length leaf chain forklift chain on a 24 hour basis. Our Worldwide freight relationships allow us to serve markets around the world so that our bearings can meet the ship at the port if necessary.

Contact our Marketing Specialist:

Joe Falvey – E-mail

Phone: 1.866.995.8760