Power Generation

The power generation industry encompasses a range of operations, including the generation, transmission, distribution, and sale of electric power. Bearings play an essential role in these applications as critical components of equipment (e.g., compressors, motors, pumps, etc.). Below, we highlight the types of bearings used in the power generation industry and their typical applications.

Types of Bearings Used in the Power Generation Industry

In the power generation industry, equipment requires uninterrupted bearing service. That’s why the bearings used must be designed and constructed for reliability and durability. The types of bearings commonly found in power generation equipment include:

- Ball and roller bearings

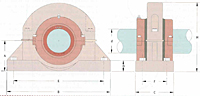

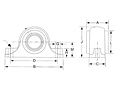

- Pillow block bearings

- Blade bearings

- Yaw bearings

- Radial bearings

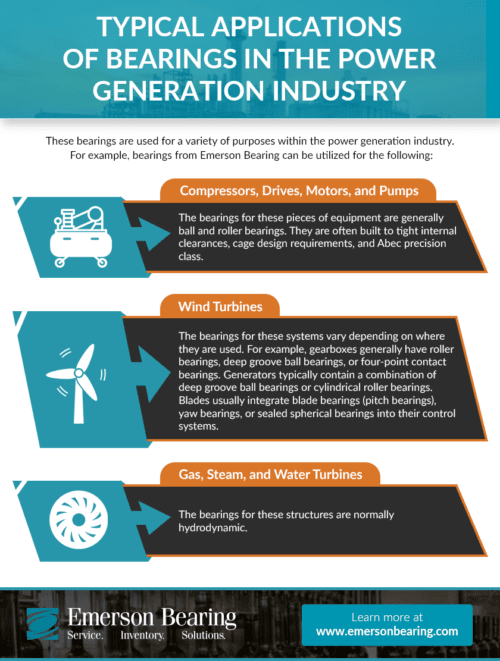

Typical Applications of Bearings in the Power Generation Industry

These bearings are used for a variety of purposes within the power generation industry. For example, bearings from Emerson Bearing can be utilized for the following:

- Compressors, drives, motors, and pumps. The bearings for these pieces of equipment are generally ball and roller bearings. They are often built to tight internal clearances, cage design requirements, and Abec precision class.

- Wind turbines. The bearings for these systems vary depending on where they are used. For example, gearboxes generally have roller bearings, deep groove ball bearings, or four-point contact bearings. Generators typically contain a combination of deep groove ball bearings or cylindrical roller bearings. Blades usually integrate blade bearings (pitch bearings), yaw bearings, or sealed spherical bearings into their control systems.

- Gas, steam, and water turbines. The bearings for these structures are normally hydrodynamic.

Emerson Bearing: Your Partner & Expert for All Bearing Needs

At Emerson Bearing, we are proud to offer custom bearing solutions tailored to the needs of the customer. Equipped with over 50 years of experience providing industry-leading ball and roller bearings, a highly knowledgeable customer service team, and a global supply network, we have what it takes to provide bearings for nearly any industry or application. We can provide quality bearings for equipment utilized by various companies throughout the power generation industry.

For more information about our bearing solutions and how we serve the power generation industry, contact us today. To discuss your bearing needs with one of our team members, request a quote.

Contact our Marketing Specialist:

Rick Piracini – E-mail

Phone: 1.866.995.8765