Track Rollers

Track rollers are available with outer ring running surfaces or cylindrical (or flat) outer ring running surfaces. While the ideal variety of track roller varies depending on intended use and application, the outer ring running surface is widely considered the gold standard.

Selection Considerations for Track Rollers

Industry experts employ track rollers to solve a variety of challenges. However, selecting the proper track roller for your application depends on several considerations, including:

- What type of load are you moving? Track roller assemblies are designed to support either moving (dynamic) loads or stationary (static) loads.

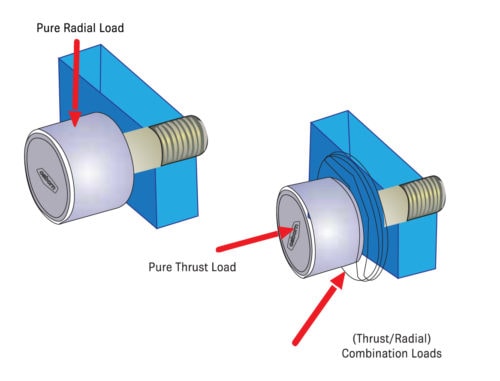

- How will the load be applied? Track rollers can support radial or axial (thrust) loads. Radial loads are applied at 90 degrees to the bearing bore or axis of rotation, while thrust loads are applied parallel to the bearing bore or axis of rotation.

- What are the motion requirements and restrictions? Load bearing assemblies are typically designed to facilitate movement in some directions while restricting motion in others.

- What is/are the applied speed(s)? The speed of the moving object can be described in terms of linear (distance over time, such as FPM or M/sec) or rotational (revolutions per minute or RPM) movement.

Key Features of Track Rollers

Although there are similarities between track rollers and cam followers, there are notable differences between the two components, particularly in regards to their intended use. For example, cam followers are generally used to handle radial loads, while track rollers are specifically designed to handle applications with a combination of axial and radial loads. Additionally, track rollers are more effective at supporting axial loads than many standard cam followers.

Additional features of track rollers include:

- Use of tapered roller bearings or ball bearings to handle radial and axial loads

- Special seals for extreme environments and operating conditions (lifelong seals and lubrication that withstand dirt, sand, and moisture)

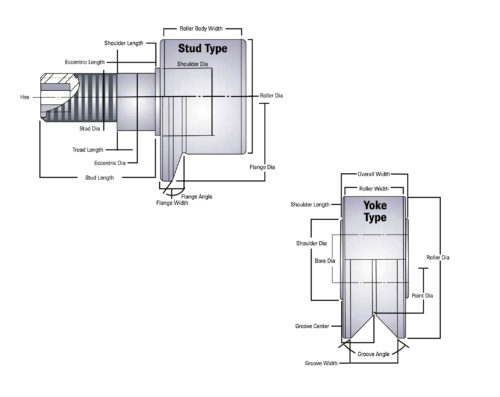

- Availability in inch and metric sizes in stud- or yoke-type varieties with options for larger sizes suitable for heavier radial and thrust loads

- Inclusion of thru-shafts

- Integration of high-shear strength studs with a hex socket for ease of installation

Engineered Rail Systems

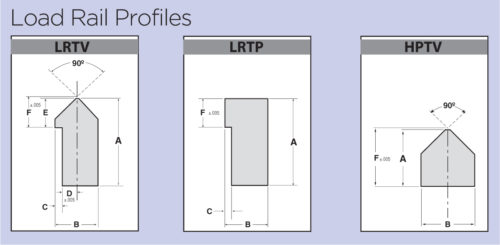

Despite the numerous advantages afforded by employing track rollers, many bearings fail to reach their full potential. This result stems from many customers attempting to run track rollers on inexpensive load rails. Although engineered rail systems—such as those provided by Emerson Bearing—are more expensive, when used with track rollers, they allow for longer bearing service lives and improved project results.

Track Roller Configurations at Emerson Bearing

At Emerson Bearing, we offer four configurations of track rollers. We represent several brand names and provide interchange resources for:

- Plain O.D. Suitable for handling thrust or radial loads which ride against the O.D. or face of the bearing

- Flanged O.D. Designed for side guiding and for loads that ride up against the flange

- V-Groove. Designed for use on V-shaped tracks, which minimize contaminant buildup

- U-Groove. Custom-made and commonly utilized for wire guiding

Some examples of custom designs and special features for track rollers include:

- Crowned profiles

- Double-flange rollers

- Non-metallic construction materials (e.g., urethane, nylon, etc.)

- Specialty plating (e.g., zinc, chrome, etc.)

- Specialty seals and lubricants

- Operating temperatures ranging from -30–225 °F

- Special seals and lubrication provisions allow for operations in extreme temperature environments from -40–325 °F

Applications of Track Rollers

Track rollers find application in a wide range of use cases, such as robotic welders, assembly and paint line conveying systems, automated storage and retrieval systems, and fracking equipment. Some of the typical industries which employ track rollers include:

- Architectural

- Automotive assembly

- Cement and concrete plants

- Fiberglass manufacturing

- Food and beverage production

- Foundries and mills

- Medical

- Metal processing

- Mining

- Pharmaceutical

- Pulp and paper

- Sand and gravel

- Scientific research

- Shipbuilding

- Wood products

Track rollers are available to suit the needs of special applications:

- All stainless construction for corrosion resistance

- High temp construction for up to 325 °F max (continuous) with high temp seals and lubricants

- Non-metallic treads that are non-marking and non-sparking, available in nylon and urethane

- The above are available with Plain Concentric Stud, Flanged Concentric Stud and V-Grooved Concentric Stud

Contact Emerson Bearing for Your Track Roller Needs

At Emerson Bearing, we offer track rollers designed to handle both radial and axial loads. With over 50 years of experience in bearings, we have the skills and knowledge to provide the optimal rollers for any application. No matter how unusual or complex the project, our team is well-equipped to find a solution for your exact track roller needs.

For more information about our track roller offerings, contact us today.