Plastic Bushings

For many years, metal bushings were the only option for industrial use. Today, newer plastic manufacturing technology allows for the production of composite plastics that serve as suitable alternatives to metal construction material for bushings.

Request for all options and dimensionsSome of the key characteristics of composite plastic bushings are:

- Low wear rates

- Light material weight

- Low coefficient of friction (which it maintains under heavy load)

- Ability to conform under load

- High-performance ratings (comparable to other sleeve bearing materials)

- Compatibility of OD with standard sintered bronze sizes (which facilitates upgrades)

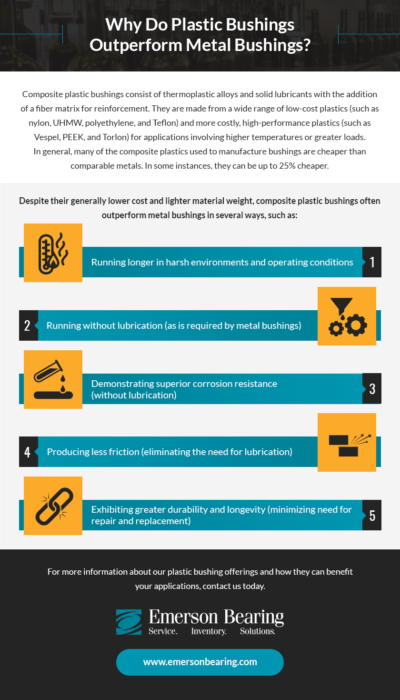

Why Do Plastic Bushings Outperform Metal Bushings?

Composite plastic bushings consist of thermoplastic alloys and solid lubricants with the addition of a fiber matrix for reinforcement. They are made from a wide range of low-cost plastics (such as nylon, UHMW, polyethylene, and Teflon) and more costly, high-performance plastics (such as Vespel, PEEK, and Torlon) for applications involving higher temperatures or greater loads. In general, many of the composite plastics used to manufacture bushings are cheaper than comparable metals. In some instances, they can be up to 25% cheaper.

Despite their generally lower cost and lighter material weight, composite plastic bushings often outperform metal bushings in several ways, such as:

- Running longer in harsh environments and operating conditions

- Running without lubrication (as is required by metal bushings)

- Demonstrating superior corrosion resistance (without lubrication)

- Producing less friction (eliminating the need for lubrication)

- Exhibiting greater durability and longevity (minimizing need for repair and replacement)

Advantages of Plastic Bushings

As outlined above, composite plastic bushings often outperform metal bushings. Some of the other advantages of using composite plastic bushings in place of metal bushings include:

- Customizable composites to meet different engineering criteria. Plastic bushings are chemical resistant, resist high temperatures up to +482°F, and are lubrication- and maintenance-free. They are available at a low cost, have a long service life, manage high loads, can be used in wet environments, are FDA approved, and have many other useful features.

- Little to no maintenance required. Plastic bushings are self-lubricating, which eliminates the need for manual application and re-application of lubrication. The elimination of lubrication also enables greater resistance to debris and other contaminants, which lowers the risk of plastic bushings seizing up.

- Lower equipment costs. Plastic bushings are highly durable due to their lower coefficient of friction and greater wear resistance. As they tend to last longer and cost less, the switch from metal to plastic can save industry professionals up to 25% in costs.

- No need for lubrication. As plastic bushings self-lubricate, they don’t attract the dirt and dust that messy grease or oil does.

- More consistent coefficient of friction. The design of plastic bushings enables them to keep a low coefficient of friction (COF), creating less heat and wear. Additionally, plastic doesn’t scratch like metal does, which helps maintain a steady COF throughout the bushing’s service life.

- Greater corrosion resistance. Unlike metal bushings, water, salt, and other chemicals do not impact the performance of plastic bushings. Similarly, unlike metal bushings, water can even be used as a lubricant in plastic bushings.

Plastic Bushings From Emerson Bearing

For more than 50 years, Emerson Bearing has provided ball and roller bearings to the domestic and international OEM and MRO markets. Our 25,000 square foot warehouse is fully stocked with a wide range of bearings suitable for all industries, including composite plastic bushings. If we don’t have it in our inventory, we can track it down for you. Regardless of the uniqueness or complexity of your application, our expert team has the skills and knowledge to find a solution that meets your bearing needs.

For more information about our plastic bushing offerings and how they can benefit your applications, contact us today.