Linear Motion Bearings

Emerson Bearing is a leading distributor of precision bearings in domestic and international markets. For over 50 years, our team has delivered high-quality products for complex operations. We are here to help you choose the right bearing systems for your equipment and projects, no matter how niche or complex. Learn more about how our linear motion bearings perform and some of the most common types of bearing systems in today’s markets.

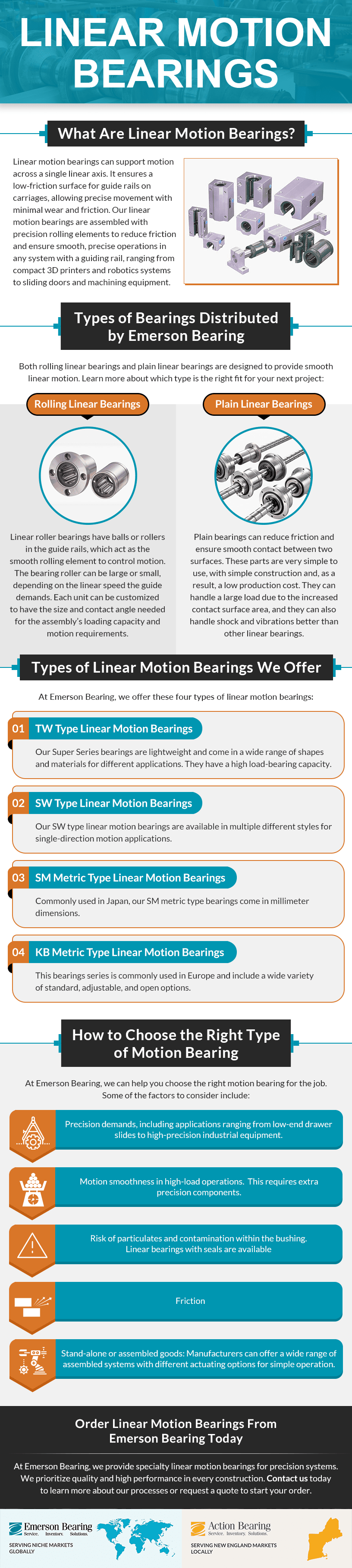

What Are Linear Motion Bearings?

There are two broad types of linear motion bearings: rolling element linear bearings and plain linear bearings. These components are found in any equipment that needs precision-controlled motion across a single axis in an X-Y plane, including consumer goods and industrial equipment. At Emerson Bearings, we can provide high-performance linear motion bearings that can fit any equipment assembly with reliable mounting equipment and long-lasting components.

Types of Linear Motion Bearings Made by Emerson Bearing

Both rolling linear bearings and plain linear bearings are designed to provide smooth linear motion. Learn more about which type is the right fit for your next project:

Rolling Linear Bearings

Linear roller bearings have balls or rollers in the guide rails, which act as the smooth rolling element to control motion. The rolling elements sit within the housing, and they may be either recirculating or non-recirculating rolling elements. The bearing roller can be large or small, depending on the linear speed the guide demands, and rolling linear bearings are one of the most common solutions for linear motion. Each unit can be customized to have the size and contact angle needed for the assembly’s loading capacity and motion requirements. Small changes in the contact angle will determine the radial loading capacity with a directly proportional relationship; the angle is inversely proportional to the lateral loading capacity. For example, a rolling linear bearing with a 45° contact angle is ideal for general movement, as it can minimize friction when loads are moving radially, reverse radially, and laterally.

Plain Linear Bearings

Plain bearings can reduce friction and ensure smooth contact between two surfaces. These parts are very simple to use, with simple construction and, as a result, a low production cost. They can handle a large load due to the increased contact surface area, and they can also handle shock and vibrations better than other linear bearings.

Types of Linear Motion Bearings We Offer

At Emerson Bearing, we offer these four types of linear motion bearings:

- TW Type Linear Motion Bearings: Our Super Series bearings are lightweight and come in a wide range of shapes and materials for different applications. They have a high load-bearing capacity.

- SW Type Linear Motion Bearings: Our SW type linear motion bearings are available in multiple different styles for single-direction motion applications.

- SM Metric Type Linear Motion Bearings: Commonly used in Japan, our SM metric type bearings come in millimeter dimensions.

- KB Metric Type Linear Motion Bearings: This bearings series is commonly used in Europe and include a wide variety of standard, adjustable, and open options.

Why Choose Emerson’s Linear Motion Bearings?

Our linear motion bearings are high-precision and highly accurate constructions. They offer some of the lowest values of friction on the market. We provide open-type constructions for fully supported ball bushings and closed-type bushings with end-supported constructions. Both our ball guides and linear guides have high load capacities due to superior construction and cutting-edge product development.

How to Choose the Right Type of Motion Bearing

At Emerson Bearing, we can help you choose the right motion bearing for the job. Some of the factors to consider include:

- Precision demands, including applications ranging from low-end drawer slides to high-precision industrial equipment.

- Motion smoothness in high-load operations. This requires materials like bronze.

- Risk of particulates and contamination within the bushing

- Friction

- Stand-alone or assembled goods: Manufacturers can offer a wide range of assembled systems with different actuating options for simple operation.

Order Linear Motion Bearings From Emerson Bearing Today

At Emerson Bearing, we provide specialty linear motion bearings for precision systems. We prioritize quality and high performance in every construction. Contact us today to learn more about our processes or request a quote to start your order.