Shaft Couplings

Shaft couplings transfer power from one rotating shaft to the next while simultaneously losing as little energy as possible and accounting for any misalignment between the two shafts. Different types of shaft couplings can also assist with auxiliary operational functions.

Emerson Bearing is a leading provider of innovative shaft couplings and solutions. Learn more about different shaft coupling types, how to choose the right fit for your assembly or product, and how to keep shaft couplings in great operational condition.

Key Considerations for Shaft Couplings

Shaft couplings must be the right fit for any particular application, but that fit depends on more than just size. Some of the most important factors to keep in mind when choosing shaft couplings include the following:

- Torque requirements

- Power transmission requirements

- Ability to compensate for vertical or horizontal misalignment

- Operational and max speed capabilities

- Environmental conditions

- Axial and angular displacement considerations

- Price

- Maintenance demands over the life of the part

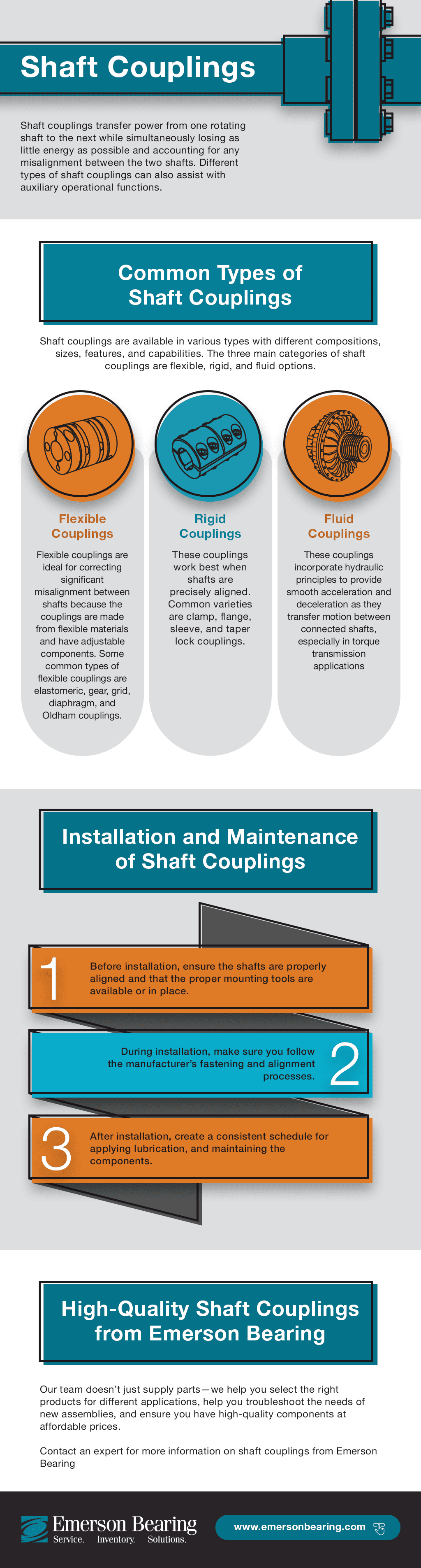

Common Types of Shaft Couplings

Shaft couplings are available in various types with different compositions, sizes, features, and capabilities. The three main categories of shaft couplings are flexible, rigid, and fluid options.

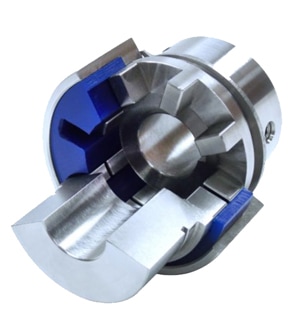

Flexible Couplings

Flexible couplings are ideal for correcting significant misalignment between shafts because the couplings are made from flexible materials and have adjustable components. Some common types of flexible couplings are elastomeric, gear, grid, diaphragm, and Oldham couplings.

Rigid Couplings

These couplings work best when shafts are precisely aligned. Common varieties are clamp, flange, sleeve, and taper lock couplings.

Fluid Couplings

These couplings incorporate hydraulic principles to provide smooth acceleration and deceleration as they transfer motion between connected shafts, especially in torque transmission applications.

Factors Influencing Coupling Selection

When you’re selecting a coupling for a specific application, it’s important to evaluate the needs of the shaft system so the new components are a long-lasting, high-performance fit. Consider the following factors:

- Torque requirements: How much torque will the coupling need to handle, including during startup, continuous operations, and shutdown?

- Shaft speed: How fast will the shafts be moving? Consider acceleration, typical speeds, and maximum potential speeds so the coupling doesn’t suffer excessive wear.

- Shaft alignment: How misaligned are the two shafts that the coupling will connect? If the shafts are significantly misaligned or might rattle around and move during operation, flexible couplings are likely to be the right choice. But if the shafts are well-aligned, a rigid coupling option is sufficient.

- Space constraints: How much space is there for the coupling? The size constraints on the thickness and dimensions of the coupling assembly will dictate the materials and style of the coupling to ensure it has the appropriate strength.

- Installation: What are the installation conditions for the coupling? Can you easily disassemble the parts as necessary to install them, or does the coupling need to have an easy installation design?

- Budget: What’s the budget? Hardier and more complex couplings will be more expensive, but they may offer greater savings than a cheaper fit over time.

- Maintenance: What maintenance considerations do you need to account for? This can include the lifespan of the product, how often hydraulic elements will need maintenance, and what environmental factors might lead to premature breakage, such as moisture leading to corrosion.

These factors, as well as unique factors for your specific application, will determine what couplings you need.

Installation and Maintenance of Shaft Couplings

Both proper installation and an appropriate regimen of preventative maintenance will make a difference in the performance and lifespan of your couplings. Take these steps before, during, and after installation:

- Before installation, prepare the shafts and hubs for the product. Ensure the shafts are properly aligned and that the proper mounting tools are available or in place.

- During installation, make sure you follow the manufacturer’s fastening and alignment processes.

- After installation, create a consistent schedule for applying lubrication, maintaining the components, monitoring for any wear or damage, and having fast repairs in the event of a problem. This keeps the coupling functional and reliable for much longer.

High-Quality Shaft Couplings from Emerson Bearing

Emerson Bearing works with organizations across every major industry, providing components like ball bearings, rollers, and couplings. We supply our clients with world-class brands such as BARDEN, EZO, FAG, GMN, INA, KBC, KOYO, NACHI, NTN, ORS, SPB, and ZKL. Our team doesn’t just supply parts—we help you select the right products for different applications, help you troubleshoot the needs of new assemblies, and ensure you have high-quality components at affordable prices. Our East Coast inventory is extensive so you have quick access to the parts you need when you need them. Contact us today to learn more about our products and processes, or request a quote to start your order.