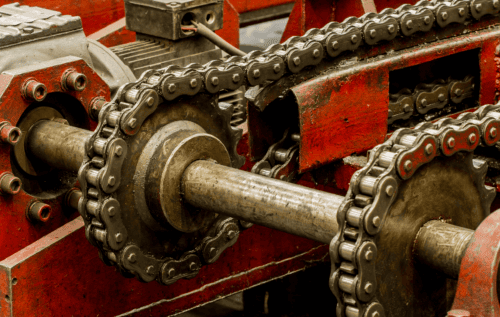

Industrial Roller Chains

Industrial roller chains are crucial in power transmission applications and modern manufacturing and processing industries to transmit power from one rotating shaft to another. Industrial roller chains are made from heavy duty metal materials and are designed to meet important mechanical specifications, including tensile strength, maximum allowable load, and chain weight. Various industrial roller chain types are necessary to accommodate different applications.

Types of Industrial Roller Chains

The types of industrial roller chains range from standard to heavy-duty to light-load capabilities to application-specific to fit a wide range of needs.

Standard Roller Chains

Standard roller chains are available from a 1/4″ to 3″ pitch as a primary way to provide mechanical power transmission. Roller chains can include options for enhancing corrosion resistance and additional attachments to accomplish specific tasks. All standard industrial roller chains must conform to JIS and ANSI standards.

Oil Field Roller Chains

Oil field roller chains are designed to resist shearing and maintain their position under stress. These high-energy chains feature, wide-waisted link plates, special hook cotters, Ballistic plates, larger-sized coated T-pins, and solid rollers with shot-peened side plates. They meet B29.1 ANSI specifications and the oil field industries’ API 7F7 standards.

Leaf Chains

Made for reciprocating motion lifting devices, leaf chains feature high load, slow speed tension linkages. These industrial roller chains are commonly made to a specific length and attach to a clevis at each end. They are available in AL or BL style, but BL is ideal to meet the ASME/ANSI B29.8 American Standard.

Heavy-Duty Roller Chains

Heavy-duty roller chains are made to the highest standards of excellence and are available in a wide range of sizes and options. Typical heavy series roller chain options include double-strand, solid bushing double-strand, and solid bushing single-strand. These industrial roller chains meet ANSI B29.1 standards but include thicker side plates than standard roller chains. The thicker plates increase the roller chain’s strength and fatigue resistance and reduce stretching and wear.

Nickel Plated Chain

Nickel-plated roller chains offer excellent corrosion resistance while delivering better strength and wear resistance than other corrosion-resistant chains. These plated roller chains are often used by companies wanting an alternative to stainless material. In applications with environments susceptible to corrosion, nickel-plated roller chains are ideal because they optimize the chain’s performance and longevity.

Hollow-Pin Roller Chains

The hollow-pin roller chain is widely utilized due to its design, which enables exceptional versatility, making it a highly popular choice among roller chain types. These industrial roller chains feature hollow-pin style bushings, allowing for attachments without taking apart the chain, and the side plate is easily removed to attach to a chain. Hollow-pin roller chains are made of stainless steel, providing excellent resistance to corrosion. Many applications use hollow-pin roller chains, such as automobile manufacturing, elevators, and packaging plants.

Applications of Industrial Roller Chains

- Conveyors: The automotive, packaging, and food and beverage industries use conveyor systems featuring industrial roller chains to help with material handling and transportation.

- Food and Beverage Processing: Several food and beverage processing equipment use industrial roller chains, such as bottling and canning machines and bakery and confectionery equipment. Stainless steel and nickel plated chains are available for corrosion resistance.

- Agriculture and Forestry: Industrial roller chains are used in combines, tractors, harvesters, and other agricultural and forestry equipment.

- Packaging: Packaging machinery use industrial roller chains for sealing, labeling, and filling.

- Mining: Most mining equipment relies on industrial roller chains, including crushers, conveyor systems, and drilling rigs.

- Oil and Gas: Industrial roller chains are used in oil and gas equipment, such as pumps, compressors, and drilling rigs.

- Warehousing and Storage: Forklifts use industrial leaf chains when lifting pallets and other heavy objects. Automated guided vehicles benefit from the use of roller chains.

Industrial Roller Chains: Industries

Various industries use industrial roller chains for low- to medium-speed drives and high-speed drive applications. They are used to transfer machine-driven power for industrial uses around the globe, ranging from general industrial needs to operations in specialized areas. Industries utilizing industrial roller chains daily include:

- Manufacturing

- Transportation and logistics

- Chemical and petrochemical

- Oil and gas

- Construction

- Metals and mining

- Agricultural

- Food and Beverage

- Material Handling Equipment

Industrial Roller Chains from Emerson Bearing

Industrial roller chains are broadly used in power transmission applications, and many industries and demanding applications rely on them. Emerson Bearing provides industrial-type roller chains to meet various light and heavy-duty needs. Contact us for more information about our selection of industrial roller chains or request a quote for your specific application.